Horizontal Pressure Leaf Filter Working Process

Jan31,24

Horizontal Pressure Leaf Filter Filtration Working Process

Horizontal Pressure Leaf Filter Working Process – There are five main steps in the horizontal pressure leaf filter filtration process, namely inspection, Pre-coated filtering, circulation, filtration, emptying and filter cake blowing.

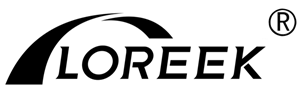

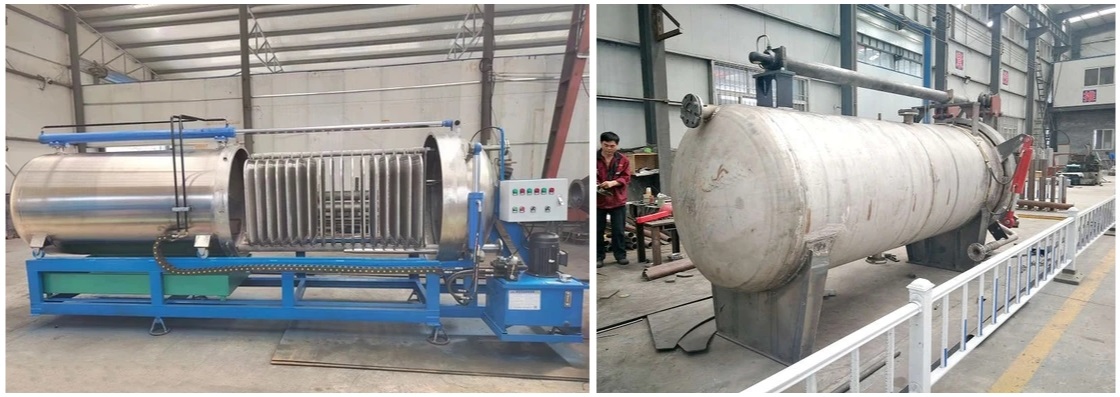

Horizontal Pressure Leaf Filter Factory Manufacturing process

Horizontal Pressure Leaf Filter Working Process Steps

Horizontal pressure leaf filter operator need to ensure All valves are closed when inspection checking. Pump valve and overflow valve need to be opened to enter the liquid. And then open the circulation valve and close the overflow vingalve to start circulation. Observe that the liquid in the watch window becomes clear and open the clear liquid valve to start filtering.

In the process of emptying and filter cake blowing, first, filtering for a period of time till little quality liquid A small amount of clear liquid flows out, or the pressure reaches the warning level, will need do the emptying and then carry out slag discharge. When unloading the slag, there needs to be no pressure in the tank, and then start the hydraulic vibration mechanism, open the head, pull out the filter leave screen, and unload the slag.

These are the basic filtration working process of the horizontal pressure leaf filters, if you want to learn more about this, just Contact Us and we will send you more info and pressure leaf filter working videos for your refer!

Reeger Pressure Leaf Filter has passed BV Approval. And our products has obtained EU CE, SGS and PED certificates. Excellent products is our brand; Attentive service is our work; Professional technique is our core. Loreek Products is your excellent Option.