Niagara Filter Leaf Supplier and Manufacturer Factory in China

Niagara Filter leaf biggest advantage is getting more and more economic benefits durning long terms operations. Pressure Leaf Filter with Niagara type filter leaf can greatly increasing the filtration capacity, save labor cost, save filtering materials, easy and quick cleaning ruducing the downtime and little waste disposal etc. Loreek Machinery can custom different sizes, shapes and materials of the filter leaves to fit almost any brand and type of pressure leaf filters, no matter vertical type pressure leaf filter or horizontal pressure leaf filters. We can also do the niagara filter leaf OEM services for you.

Description

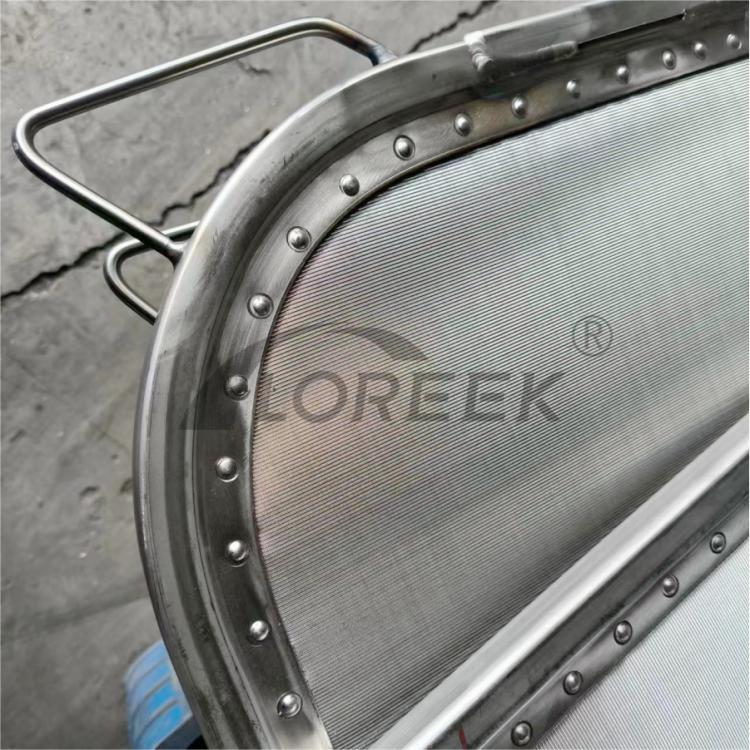

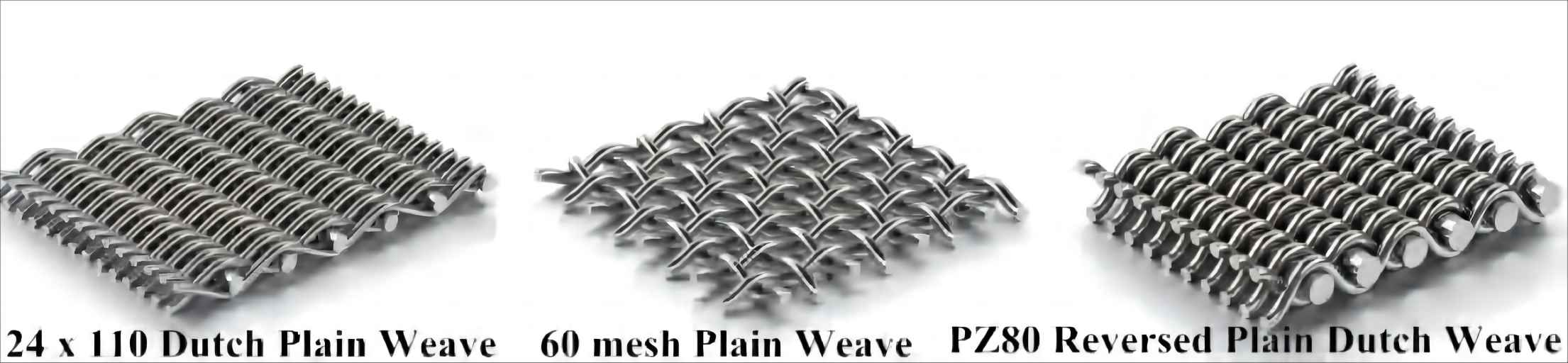

Niagara filter leaf is main filtering parts for pressure leaf filters achieving the solid liquid pressure leaf filtration work process. Niagara type filter leaf consists of 5 layers of stainless steel 304 or 316L material structure. strong structure and not easily deformed make the filter leaf has long working life and commercial benefits advantages, surface screen of the niagara filter leaf can custom according to your filtration size and characteristics of Filtered Particulate Matter. and loreek machinery can free do the filtering test for you. Niagara filter leaf normal has 5 layers. Inside one layer as structural support and drainage functions, mesh size is big. Two layers on each surface of the inside layer also as the structural support layer for the filter leaves, these 2 layers has small mesh size and also can protect the outermost filter layer screen. the last are the two layers of customized mesh size of the fine filter mesh screen on the surface of the filter leaves. These are the basic structure of the niagara filter leaves, and then the 5 layers will be put into customized tubular frame borders and are made leak proof by machine riveting or bolting depending on the pressure leaf filter filtration applicatons and customer requirements. Pressure leaf filter is a full closed pressure vessel with multiple niagara filter leaves arranged and installed in an output pipe. In order to increase the pressure leaf filter filtration surface area for achieving large filtering capacity, a number of filter leaf units can be connected in parallel. The connection between the outlet of the filter leaf plate and the output pipe is made of sealing rings and special structural design to achieve a sealed connection. The pressure leaf filter operates by pumping the slurry or liquid into the pressure vessel, as the closed structure and continue pumping pressure forces the liquid through the pressure leaf filter leaves surface screen and the filtered particles are intercepted on the surface of the filter. With continuous accumulation, a pre-coated filter layer is gradually formed on the surface of the filter leaf and the filtered liquid flows out from the out pipe, by these steps achieving the filtration work. Niagara filter leaf has advantages like strong and sturdy structure, corrosion-resistant, easy to clean etc. These features and advantages make the Niagara filter leaf pressure leaf filters can be applied in almost all industry. Following are the most experienced Loreek Niagara pressure leaf filter applications like: diesel & Biodiesel, lithium battery coolant, soap raw materials, lubricants and oil, glue, chemical fiber, electrophoretic paint, catalyst, varnishes and topcoats, beer, syrup sugar, wine, sake, liquor, fruit juice, soda filtration, syrup, food additives etc. Loreek Machinery is an experienced pressure leaf filter supplier and manufacturer in China. and we have done the Niagara type pressure leaf filter exporting since 2015. Till now we have serviced hundreds of overseas customers success solving their pressure leaf filtration problems. All our cooperative customers, the spare parts and main parts of their pressure leaf filters, all are factory wholesale prices promise. Niagara type filter leaf is the most type of filter leaf we supply. Loreek Machinery can provide the most competitive prices Niagara filter leaf OEM service and fast delivery time guarantee. Just Contast Us Now for more info. Niagara Filter Leaf is a mature product has serviced the pressure leaf filter marketing for many years. Loreek Niagara filter leaf for our pressure leaf filters is manufactured in strict accordance with international standards. All stainless steel 304, 316L or custom materials are National standard. Our product has many advantages like: 5 layers strong structure can guarantee the filter leaf can withstand high pressure and no deformation. Stainless Steel material ensure high temperature and preservative. All these features and advantages ensure the niagara filter leaf type pressure leaf filters widely applied for the chemical filtration applications. Niagara Filter leaf biggest advantage is getting more and more economic benefits durning long terms operations. Pressure Leaf Filter with Niagara type filter leaf can greatly increasing the filtration capacity, save labor cost, save filtering materials, easy and quick cleaning ruducing the downtime and little waste disposal etc. Loreek Machinery can custom different sizes, shapes and materials of the filter leaves to fit almost any brand and type of pressure leaf filters, no matter vertical type pressure leaf filter or horizontal pressure leaf filters. We can also do the niagara filter leaf OEM services for you.Niagara Filter Leaf Best Equip for Pressure Leaf Filters

Niagara Filter Leaf Factory Manufacturing

Niagara Filter Leaf Structure Features

Niagara Filter Leaf Surface Screen Types

Why Niagara filter leaf is the key for pressure leaf filter filtration working?

Niagara Filter Leaf Type Pressure Leaf Filter Applications

Niagara Type Pressure Leaf Filter Applications

Why buy Niagara Filter Leaf from Loreek Machinery?

Niagara Pressure Leaf Filter Advantages

Niagara Pressure Leaf Filter Supplier and Manufacturer