Pressure Leaf Filter

Loreek Pressure Leaf Filter China Supplier and Manufacturer for Your Efficient Filtration Applications

Pressure Leaf Filter has two types: vertical pressure leaf filter and horizontal pressure leaf filter, main big difference is the filtration capacity, working space limit and cake discharging requirements.

Pressure leaf filter can ensure the industrial filtering working processes are continuous automated operations without affecting normal production. The application of pressure leaf filters is conducive to improving the production efficiency of enterprises and reducing the operating costs of the filtration process.

Pressure leaf filter has features of high temperature resistance, silicone rubber sealing rings for all sealing parts. Non-toxic, no leakage, good sealing performance. Loreek Machinery can also customize a multi-stage pressure leaf filter filtration system according to customer needs, which can accommodate coarser filter materials, and the second stage can accommodate turbid filter materials, which not only saves time but also improves filtration accuracy.

Loreek Pressure leaf filter is a highly automated solid liquid pressure filtration working equipment. It has the functions of automatic liquid feeding, fine filtration, filter leaves washing, slag auto or semi-auto removal and filter leaves screen cloth cleaning.

Pressure Leaf Filter Vertical and Horizontal Types

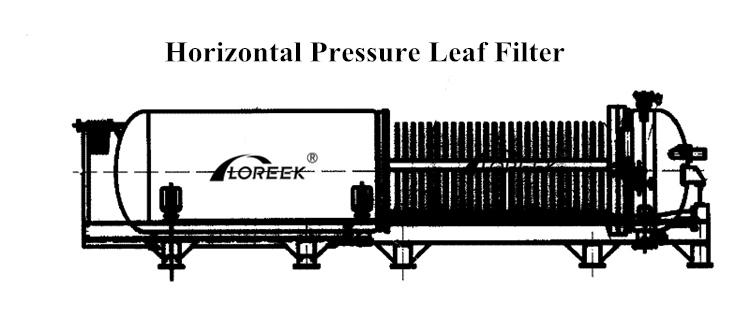

The Max. Filtration area of the horizontal pressure leaf filters can be 200 M². The usual materials of the pressure leaf filter vessel is carbon steel and the filter leaves elements can be stainless steel 304 or 316L and we can also custom the pressure vessel for your special filtering applications.

Choosing A Reliable Pressure Leaf Filter Manufacturer

It is critical to choose a reliable pressure leaf filter manufacturer for addressing your material filtering needs. Looking for a trusted manufacturer and supplier? Contact Loreek Machinery Now! You can learn about how we help you achieve your goals.

We offer unique quality pressure leaf filter for years of trouble-free operation.

Custom design is available to meet your specific solid liquid separating requirements.

At our company, you can get a quality pressure leaf filter at a factory wholesale low price.

Perfect after-sales service team can help solve any problem you have in the filter operation and maintenance.

To get the right type of pressure leaf filters for your application, and also at a reasonable price, get in touch with our sales manager today!

Pressure Leaf Filter Competitive Prices and Best Service for you!

Horizontal Pressure Leaf Filter Structure Design Drawings

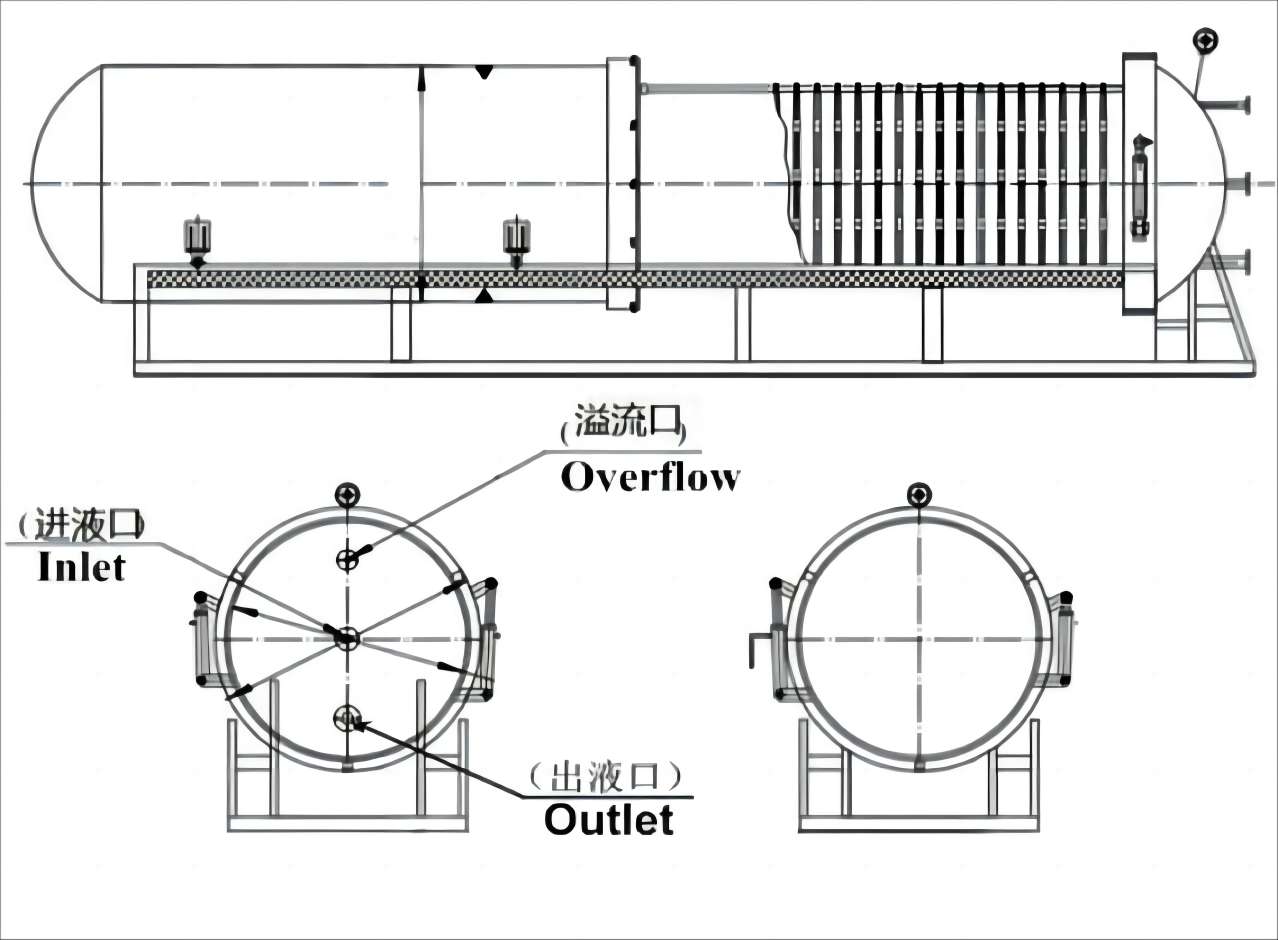

Vertical Pressure Leaf Filter Diagram Structure Design Drawings

Why Buy Pressure Leaf Filter from Loreek Machinery?

First, Loreek Machinery has strict quality management system for pressure leaf filter manufacturing raw materials and spare parts and we only cooperate with the Long-term, stable and quality-assured parts and raw material suppliers.

Second, Loreek Machinery Honored ISO 9001 Quality management system certification, we have an experienced pressure leaf filter processing and manufacturing team, guarantee the processing quality and standard of the products, and after each process, we also will do the Detections. Especially for the filter leaves, we have a strict processing procedures like the structures, each layers, filtering screens etc.

Third, After the pressure leaf filter is manufactured, The workers will finally do the pressure and sealing testing of the pressure leaf filter pressure vessels and the filter leaves. All Qualified. Finally, an excellent pressure leaf filter is ready for our customers.

Loreek Pressure Leaf Filter get the CE SGS and BV certificates. High quality standard and meeting different countries and regions requirements.

Solid liquid separation equipments are most common and important equipment in many factories. There are many type of filters, different filter manufactures, most important, different industry filtration require different filtration solutions.

Loreek Machinery is an experienced pressure leaf filter factory manufacturer after long-term of servicing hundreds of companies and factories solving their filtration problems, we understand customer autual filtration needs and our special design pressure leaf filters meet the special industrial filtration needs of different customers.

You can always trust us and loreek machinery will do our best for your each pressure leaf filter orders.

Tel:+8615136746155

Email: info@loreek.com

Loreek Pressure Leaf Filter Factory Manufacturing Process Pictures

Pressure Leaf Filter Features

Pressure Leaf filter refers to a filtration equipment suitable for solid liquid filtration and separation processes such as decolorized oil filtration, clarification filtration, and crystallization in the production of oil, molten sulfur, paraffin wax, chemical, pharmaceutical and other industries.

Compared to other solid liquid separation equipments, the pressure leaf filters can be more efficient and accuracy for your filtrations, easy operating and large filtering capacity, easy cleaning for the filter leaves and auto dry cake discharging, also full enclosed structure more environmental friendly and healthy safe for the operating workers.

1. Max. 200 M² Filtering working Areas Horizontal Pressure Leaf filter Design.

2. 5 Layers of the filter leaves strong structures.

3. Vertical and Horizontal type of the filter pressure vessel. Compact structure design and small footprint.

4. Stainless Steel 304 or 316L for filter leaves Food grade, durable and more preservative.

5. Automatic semi-automatic slag discharging design.

6. Pressure Leaf Filter apply for almost all solid liquid filtration applications.

7. Easy operating and Efficiency and accurate results.

8. No leakage with well sealing functions.

Pressure Leaf Filters Pictures Show

Pressure Leaf Filter Advantages

Pressure leaf filter has the advantages of compact structure, small footprint; good filtration effect, high filtering precision, low loss; auto control pneumatic vibrating slag discharge, avoiding manual slag cleaning, More thorough and efficient, easy operation, low labor intensity etc.

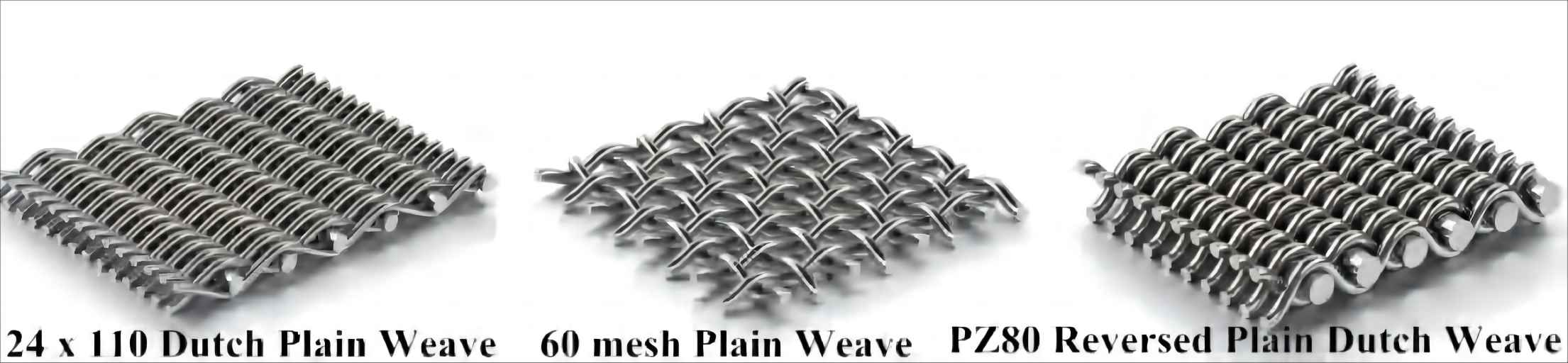

By using stainless steel 304 or 316L 5 layers pressure leaf filter leaves’ screen mesh, avoiding the disadvantages of replacing filter cloth or filter paper, reducing cost, improve production efficiency, and can achieve continuous filtration working process productions. Fully enclosed structure operation, environmentally friendly, and low material loss.

Pressure Leaf Filter Main Parts – Filter Leaves elements

Pressure Leaf Filter Leaves Mesh Size Technical data

| Construction | Mesh | Wire Thickness mm | Micron Rating |

| 1Ply of drainage mesh | Plain Weave 4×4 | 1.6 | 4750 |

| 2Ply of support mesh | Plain Weave 8×8 | 0.7 | 2470 |

| 2Ply of filter mesh | Plain Weave 60 mesh | 0.19 | 250 |

| Plain Dutch Weave | 0.35/0.25 | 125 | |

| Reversed Dutch Weave,PZ80 | 0.2/0.4 | 80 |

Pressure Leaf Filter Leaves Structures

How to choose a pressure leaf filter?

Pressure leaf filter relies on the filter leaves to intercept impurity particles and form a filter cake to filter materials. Therefore, the selection of a pressure leaf filter depends on the amount of filtering cake to be discharged for each filtering as the main parameter, followed by the output you require. and the fluidity of the material. After understanding these three parameters, you can choose the filtration area of the pressure leaf filters.

Vertical pressure leaf filter working area can from 1 to 100 m2. Horizontal pressure leaf filter Max. filtering area can be 200. Welcome to Contact Us and we can also custom for your filtration requirements.

Pressure Leaf Filter can also equipped with a reflux device. Cleaning is extremely convenient. After the pump stops rotating, open the backflow valve, and all sediment will automatically flow back out. At the same time, you only need to use clean water to backwash from the backflow to clean it.

Loreek Machinery will Work together to conduct comprehensive and thorough communication with you and Work together to conduct comprehensive and thorough communication, finally choose one most suitable and right pressure leaf filters for your solid liquid separation applications.

Pressure Leaf Filter Industrial Filtration Applications

Pressure leaf filter is applied for solid liquid filtration for almost all industrial. Our experienced industrial filtration applications are like: Bleaching earth, Fatty acids, crude oil, Ni-catalyst, Biodiesel, Brine, Fructose, Glucose, Molten Sulphur, Dewaxing & Winterization, Chemicals, Minerals, food & Beverages, Sugar Industries etc.

Pressure Leaf Filter Applications Marketing

Edible Oils. Edible oil coarse filtration, bleached oil filtration,crude oil, winterized oil, etc

Food & beverage. gelatin processing, Pectin processing, vinegar, starch, sugar juice, sweet water, etc.; beer, juice, wine, milk, Glucose, sweeteners, sugar, fruit juice production, etc.

Molten sulfur filtration

Chemicals and oleochemicals

Organic and inorganic salts, amines, resins, etc

Filtration of Carbon Black and Bleaching Earth in Edible Oil Processing

Post Bleaching, Post Cooling Applications in Refinery

Petrochemicals. Diesel oil, Bio fuels, lubricating oil, petroleum wax, mineral oil products, etc.

Fine chemicals. Resins, varnishes, dyes, lacquers, etc.

Organic chemicals. A variety of organic acids, alcohols, benzene, aldehydes, etc.

Inorganic chemicals. Bromine water, potassium cyanide, fluorite, etc.

Biodiesel production (pre-treatment and polishing)

Vertical Pressure Leaf Filter Working Applications

Horizontal Pressure Leaf Filter Working Process

Pressure Leaf Filter Working Principle

The pressure leaf filter uses pressure and vacuum suction as power to complete the filtration process. At the same time, when the material passes through the sedimentation zone, the particles of solid matter are arranged in an orderly manner. Large particles are arranged on the bottom layer and small particles are arranged on the upper layer. In this way, the leaf filter can obtain better results. The filter cake structure reduces the permeability resistance of the filtrate and increases the filtration speed. Sealed filtration without any environmental pollution. It occupies a small area and is easy to operate.

The horizontal design of the filter plate ensures stable filter cake formation and good filtration effect. Centrifugal slag discharge, clean and fast, suitable for slag discharge and filtration of materials with various viscosities. The filter is easy to clean without disassembly and assembly, and can be done inside the machine. The entire filtration process can be automated.

Vertical Pressure Leaf Filter Working Process for Crude Oil Filtering

Pressure Leaf Filter Brief Technical Specification

Working Pressure: 0.1 – 0.49Mpa

Pneumatic Vibration Frequency: 3000 to 4500 times/min

Solid Content in liquid: 0.05% to 0.2%

Liquid Content in salg: ≤20%

Filtration Area Capacity: 1m²-200m²(Custom version available)

Pressure Vessel diameter:460-2500mm,others on request

O-ring sealing material: Viton,EPDM,Nitrile,Silicon

Filter leaves Materil: Stainless Steel 304 or 316L

Maximum operating pressure: 0.6Mpa

Maximum operating temperature: up to 150℃

Core Components: PLC System, Pressure Vessel, Gear, Pump

Pressure Vessel material: Carbon Steel, stainless steel 304,316L or custom.

Pressure Leaf Filter Main Components

The main body of the pressure leaf filter is a closed tank(standard pressure vessels), with multiple filter leaves placed vertically inside as filter elements. The pressure leaf filter is working through pressure or vacuum, and the two filter tanks are connected alternately for continuous filtering. According to the requirements of different materials, filter aids can also be added to prepare the mixing barrel, and filter aids such as diatomaceous earth, perlite, and activated clay can be pre-applied on the filter leaves. This pressure leaf filter machine has small size, high filtration efficiency, low material consumption and high filtrate clarity.

Pressure Leaf Filter Technical Parameters

| Model | Filter area | Diameter (mm) | Plate Pitch | Inlet | Outlet | Overflow | Slagging Port | Height | Weight |

| (m2) | (mm) | (mm) | port | (mm) | (mm) | (kg) | |||

| VPLF-4 | 4 | 550 | 70 | DN50 | 80 | DN32 | 300 | 1950 | 460 |

| VPLF -7 | 7 | 650 | 70 | DN50 | 80 | DN32 | 400 | 2150 | 890 |

| VPLF -10 | 10 | 800 | 70 | DN50 | 80 | DN32 | 400 | 2300 | 1200 |

| VPLF -15 | 15 | 900 | 70 | DN50 | 80 | DN32 | 400 | 2300 | 1500 |

| VPLF -20 | 20 | 1100 | 75 | DN50 | 80 | DN32 | 400 | 2500 | 1800 |

| VPLF -30 | 30 | 1200 | 75 | DN50 | 80 | DN32 | 400 | 2600 | 2100 |

| VPLF -40 | 40 | 1300 | 75 | DN70 | 80 | DN40 | 500 | 2800 | 2500 |

| VPLF -50 | 50 | 1400 | 75 | DN80 | 80 | DN50 | 500 | 2800 | 2800 |

| VPLF -60 | 60 | 1500 | 75 | DN80 | 80 | DN50 | 600 | 3200 | 3200 |

| VPLF -80 | 80 | 1600 | 70 | DN80 | 80 | DN50 | 600 | 3600 | 3600 |

| VPLF -90 | 80 | 1800 | 70 | DN80 | 80 | DN50 | 600/800 | 3870 | 4500 |

Pressure Leaf Filter Packaging & Shipping Standards

Loreek Machinery has done the pressure leaf filter exporting for many years since 2015. and the following are some basic of our packaging standard for the pressure leaf filters.

1.Waterproof packaging with the international exporting standard and Steel strip reinforcement for safe.

2. Spare parts, Electric Motor and Power Cabinet will be packed in Wooden Case or Iron Box with multi-layer cushioning bubble film. Other equipment will be packed by Color-Stripes Plastic Cloth.

3. Or as per customer’s requirements.

Vertical Pressure Leaf Filter Packaging within Containers

How Pressure Leaf Filter cake slag discharging?

The cake outlet of the pressure leaf filter can be Fully automatic and semi-automatic. After washing the filter cake with detergent,the cake can be heated and dried in the vessel by using steam,air or nitrogen.

The pnuematic vibration system strong vibrating forces and frequency to the filter leaves let the dry cake discharge easy and quick. together with the gentle gas expansion of the filter leaf.The gas is purged backwards through the filter and pushes the dry cake off the leaf surface.

The cake outlet opening must be interlocked with a pressure sensor to avoid openingunder pressure. On some filters the cloth or mesh screen may be backwashed withwater after cake discharge to dislodge and remove any cake residue that adhered tothe medium.

Niagara Pressure Leaf Filter Factory Manufacturing Process

Pressure Leaf Filter FAQ

What are pressure leaf filter types?

Pressure leaf filter can be divided into vertical and horizontal types according to their shapes.

What are the structure material of pressure leaf filters?

Pressure Leaf FIlter main componments are the pressure vessel and filtering elements – niagara filter leaves. For the pressure vessel normal structure material is carbon steel and can also be Stainless Steel 304. for the filter leaves now our standard structure material is Stainless Steel 304 or 316L or can also custom for your special filtration requirements.

Are you a factory or trading company?

Loreek Machinery is an experienced pressure leaf filter factory manufacturer and supplier in China. We have done the pressure leaf filter manufacturing and Exporting trade business since 2012. over 30 countries and areas excluding China mainland, Southeast Asia, West Asia, South Asia, Northeast Asia, Middle East, Europe, North America, South America , Africa, Oceania and so on. LOREEK Brand has been one excellent option in this industry.

What certificates you honored for your company and products?

Up to now, Loreek Machinery has passed BV Approval and ISO 9001. And our pressure leaf filter products has obtained EU CE, SGS and PED certificates. Excellent products is our brand; Attentive service is our work; Professional technique is our core. Loreek Products is your excellent Option.

What is the delivery time of your products?

Like Pressure leaf filter products, for normal standard model, 7 working days can quality done and delivery to you. fo special custom requirements, 10 to 25 working days. We guarantee we will do our best for fast delivery time and we can tell you the delivery time with quality products standard is our advantages. Many customers are Very satisfied with our delivery time.

You can contact Loreek Machinery directly, and our professional engineers are always here to help you.