Pressure Leaf Filter Niagara Filter Leaf Features and Advantages

Pressure Leaf Filter is an efficient pressure leaf filtration equipments and are now widely used in many industrial like chemical, medical, pharmaceutical, food processing and other fields. Compared with other filtration devices, Niagara type pressure leaf filter has a larger filtering capacity for loading media, so the efficiency is generally higher. Due to the fully enclosed design, there will be no problems such as leakage and environmental pollution. As for the niagara filter leaf, workers can pull out automatically, making it very easy and convenient to inspect and maintain.

Description

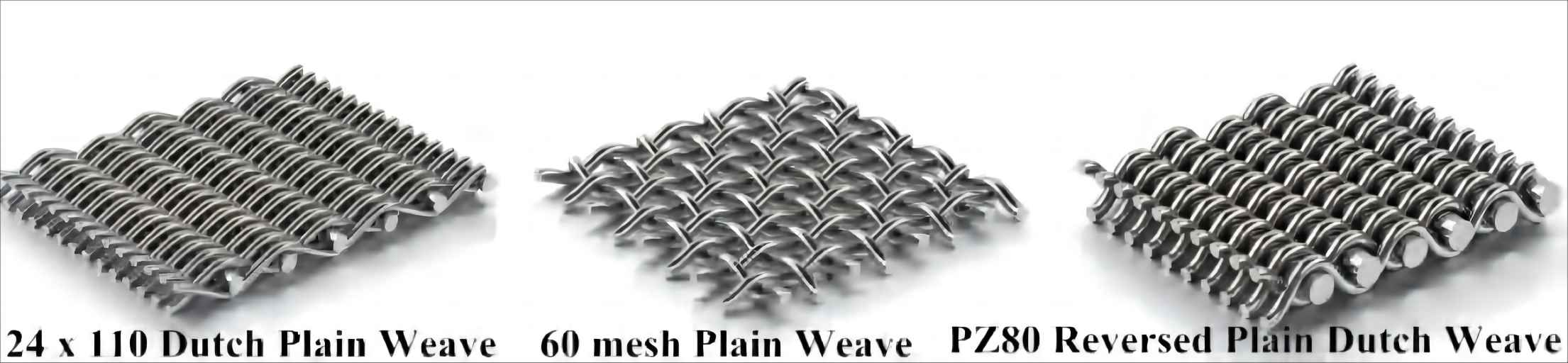

Pressure Leaf Filter is an efficient pressure leaf filtration equipments and are now widely used in many industrial like chemical, medical, pharmaceutical, food processing and other fields. Compared with other filtration devices, Niagara type pressure leaf filter has a larger filtering capacity for loading media, so the efficiency is generally higher. Due to the fully enclosed design, there will be no problems such as leakage and environmental pollution. As for the niagara filter leaf, workers can pull out automatically, making it very easy and convenient to inspect and maintain. The pressure leaf filter does not require filter cloth or filter paper, greatly reducing filtration costs. Fully enclosed structure and automatic operation, environmentally friendly, no material loss. Vibration cake slag removal greatly reduces labor intensity and enables continuous operation. The pneumatic valve discharges slag, which greatly reduces the labor intensity of workers. For filtration or dehydration filtration of slag or activated carbon (white clay) in liquid, this is why the niagara pressure leaf filter can completely replace the plate and frame filter and is an ideal equipment in the filtration industry. The type, size, model and filter leaf plates of the niagara filter are determined by many factors. Controlling factors include process type, importance of filter cake or filtrate, particle type and content, process fluid, temperature, and pressure. The importance of filter leaf plates is self-evident. The main purpose of the Niagara filter leaf is to provide a filtering screen surface for carrying filter aid, and what performs the actual filtration is the filter aid coating (pre-coating) formed on the niagara filter surface. The size of the filter aid is determined by the condition and size of the contaminants. Then determine the mesh and weave type of the leaf filter plates according to the type and specification of the filter aid. When the pressure filter leaf screens are pre-coated, the material to be filtered enters the filter. As the clear liquid passes through, contaminants are trapped on the precoated surface. This is the actual filtration process.Niagara Pressure Leaf Filter factory show

Niagara Filter Leaf Features and Advantages

Niagara Filter Leaf Detail Pictures

Niagara Filter Leaf screen mesh types

Pressure Leaf Filter Niagara Filter Leaf Working Process

Send Inquiry

You Might Also Like

-

Edible Oil Filtration Polishing Filter Manufacturer

-

Niagara Pressure Leaf Filter Mesh Size for Pre-coating Layer

-

Pulse Tube Filter Pressure Filtration Applications

-

Pressure Leaf Filter Maintenance Manual Tips

-

Pressure Leaf Filter Filtering Leaves Cleaning and Maintenance

-

Pressure Leaf Filter Cake Slag Discharging Tips for successful operation