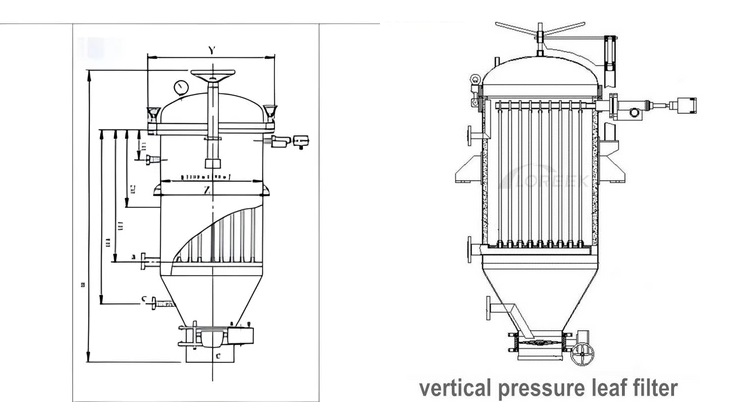

Vertical Pressure Leaf Filter Supplier and Manufacturer in China

Vertical Pressure Leaf Filter is a pressure leaf filtration equipment adopts a vibration slag discharge design, with multiple filter leave plates integrated inside the unit. The filter leave plate is composed of multiple stainless steel 304 or 316L filter leaf plates and is installed on the header inside the cylinder. When the filtration time or pressure difference reaches the set value, after the liquid is discharged, the vibrating slag discharger vibrates to remove the filter cake on the pressure leaf filter to regenerate the filtraton.

Vertical pressure leaf filter has a variety of structures and working forms, and uses different forms of built-in filter leave elements to effectively shield insoluble solids, suspended matter, and particulate impurities in liquid materials. After the pressure leaf filtration process enters the process setting, self-cleaning can be performed online automatic. After the quick cleaning is completed, the pressure leaf filter will be restored to its original filtration state to achieve continuous filtration operation.

Vertical Pressure Leaf Filter China Supplier and Manufacturer

Vertical Pressure Leaf Filter Working Process

Vertical Pressure Leaf Filter filtration working process is as following. When the pressure leaf filter status is normal, start the filter and the filtering liquid will pump into the machine, impurity particles will Accumulation on filter surface. the filter cake layer becomes thicker and thicker, the filtration resistance increases, and the pressure in the tank rises. When you see that the pressure gauge on the upper part of the filter shows 0.4Mpa, stop conveying liquid slurry into the filter tank. turn on the air compressor, and input air into the filter tank through the overflow port through the pipeline. Under the action of air pressure, the oil in the filter cake is gradually pressed out, and returns to the decolorization pot or mixing tank through the pipeline, about After 30 minutes, the filter cake is pressed dry, and the input of air into the filter is stopped. When the pressure gauge on the upper part of the filter shows 0, open the butterfly valve, start the vibrating body, and start discharging slag. When the slag is completely discharged, close the butterfly valve of the vertical pressure leaf filter and all valves to start the next round of filtration.

Vertical Pressure Leaf Filter Features

1. Completely sealed filtration, no leakage, and little environmental pollution.

2. The pressure leaf filter leave plate adopts a vertical design, and the filter medium is composed of stainless steel filter mesh, which does not consume filter paper, filter cloth, or filter element.

3. Vertical pressure leaf filter can achieve complete filtration at one time, especially in working conditions with high hygiene requirements, high viscosity and highly toxic conditions.

4. The filter cake can be washed and dried to obtain large economic benefits.

5. Automatic slag discharge to ensure clean slag discharge.

6. Because the filter medium is made of stainless steel filter, the filtration speed is fast and the service life is long.

7. The filter is easy to clean and does not need to be disassembled. It can be done inside the body.

8. The spacing of the filter discs can be adjusted according to different requirements, so the slag holding capacity is large.

9. The entire filtration process can be fully automated.

Vertical Pressure Leaf Filter Working Principle

Vertical Pressure Leaf Filter working principle is As the filtration time increases, more and more solid impurities are trapped, the thickness of the filter cake increases, the filtration resistance of the system increases, and it needs to be discharged when the pressure reaches the set value. At this time, by stopping the delivery of filtrate into the tank and blowing compressed air into the tank through the overflow pipe, the remaining hydraulic pressure in the tank can be put into another filter. Then turn off the compressed air, and when filtering decolorized oil or hydrogenated oil, introduce steam into the tank; when filtering crude oil and other filtrate, you can blow compressed air into the tank to dry the cake. After the cake is dry, stop the steam or compressed air, open the butterfly valve, and start the vibrator to vibrate the filter and remove the cake from the filter.

Vertical Pressure Leaf Filter Advantages

Automatic cake slag discharging

Pneumatic Mechanical vibration functions achieving automatic slag discharging with strong vibration force for more thoroughly cleaning of the vertical pressure leaf filter leave screens. Workers just operate the control box and then open the butterfly valve of the pressure leaf filter, starts the vibration slag discharge device, and vibrates to remove slag. Greatly reducing the labor intensity of workers and achieving continuous operation.

5 Layers Pressure Leaf Filter Leaves Custom Functions

No need for filter cloth and filter paper. Vertical Pressure Leaf Filter uses a special stainless steel composite woven screen as the filtering sieve with 5 layers strong structure features, which is corrosion-resistant, easy to clean, has a long life, can be used continuously for 3-5 years, and has low maintenance costs. The Filtration accuracy can be 0.3 to 100 μm.

Full enclosed Pressure Vessel Structure Environmental friendly

Pressure vessel is the main part of vertical pressure leaf filters. Complying with environmental protection standards, pipeline connection, fully enclosed filtration structure design, the filtering materials are non-volatile, no lost, and filtering good quality.

Energy Saving Low price cost and high efficiency

Vertical Pressure leaf filter can achieve continuing filtration working more efficient. Auto slag discharging save labor cost, full enclosed structure more healthy and Environmental friendly. Getting more and more economic benefits for customers.

Vertical Pressure Leaf Filter Applications

Vertical Pressure Leaf Filter is a an efficient pressure leaf filtration widely applied for almost all solid liquid pressure filtration applications. large filtering capacity, saving labor cost and environmental friendly. The application industry like: crude oil, hydrogenated oil, winterized oil, oil industry; activated carbon decoloration for granulated sugar and glucose, clarification filtering of liquor, juice, beverage and food industry; crystal separation of petrochemical industry, inorganic chemical industry and organic chemical industry, separation of catalyzers, decoloration of chemical industry.

Loreek vertical pressure leaf filter experienced industrial filtration applications are like: Miscella, Bleaching earth, Bleached and/or detoxified oil filtration, Fatty acids, crude oil, Ni-catalyst, Biodiesel, Brine, Fructose, Glucose, Molten Sulphur, Dewaxing & Winterization, Chemicals, Minerals, Deodorized oil and Winterized oil filtration, food & Beverages, Sugar Industries etc.

Vertical Pressure Leaf Filter working Applications

Vertical Pressure Leaf Filter Benefits

Vertical pressure leaf filter for your solid liquid pressure leaf filtration application has many benefits. Mechanical vibration for automatic slag removal, open the butterfly valve, start the vibration slag removal device, and remove the slag by vibration to reduce the labor intensity of workers. The specially customized filter plate does not need filter cloth and paper. The automatic slag removal filter uses a specially made stainless steel composite woven filter screen, which is corrosion resistant, easy to clean, has a long service life, can be used continuously for 3-5 years, and has low maintenance cost. Closed and environmentally friendly, in line with environmental protection standards, pipeline connection, fully closed filtration, products do not volatilize, do not throw away, and have good quality. High energy saving efficiency, filtering the residue or activated carbon (clay) in the liquid, or decolorization filtering, can replace the plate and frame filter.

Vertical Pressure Leaf Filter Operation and Maintenance Manual Tips

1. Before each filtration shift, check whether the vertical pressure leaf filter bolts are loose. If they are found to be loose, they must be tightened to maintain a good seal between the cylinder head and the pressure vessel body.

2. The pressure leaf filter with vibrator is equipped with a lubricator. Clean the lubricator and supply oil once a month to confirm that the vibrator is working properly and lubricated.

3. During the cleaning process of the filter, if the filter is accidentally scratched, it can still be used after repairing it with silver solder.

4. According to the usage conditions, after each cleaning of the filter plate, check the O-ring at the bottom of the filter plate once. If any damage is found, replace it in time.

5. When out of operation for a long time, the entire vertical pressure leaf filter machine should be cleaned, especially the filter disc should be carefully taken care of, thoroughly cleaned, and hung in a dry place to prevent the material from becoming moldy and corroding the internal parts of the machine.